JKMD(C) Series Multi-Rope Friction Mine Hoist-Mine Winder-Mine Winch

Bidragon International as the sole oversea market agent of Hebi Mine Equipment Manufacture Factory is a leading company in mine hoist/mine winder/mine winch exportation business.

We are professional manufacturer of mine hoist/ mine winder/mine winch. In past 20 years, we have produced more than 1000 sets mine hoists and winches of JK and JKMD series. The sold products are working in good conditions for our different customers and we get good reputation in mine equipments suppliers and customers. Till now, the largest mine hoist in the JK series is 2JK-6.3/20 single-rope winding mine hoist, in JKMD series is JKMD-5.7x4 multi-rope friction floor-mounted mine hoist and JKYB-3x2.5XP hydraulic anti-explosion Mine Hoist is the biggest one in it’s series.

Application: JKMD sereis mine hoist is mainly used at vertical shaft of coal mine, metalic and nonmetallic mine to lift coal, ore, material, equipment, and workers.

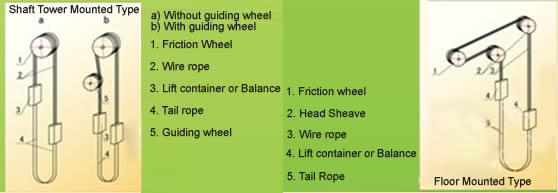

Type: Non explosion proof type. Can be Shaft Tower Mounted and Floor Mounted.

Working Principle:

1. Closed cycle wire rope which has container in middle position is winded on the mine hoist durm. When drun driven by motor rolling, the container will lift up and down through the friction between wire rope and drum.

2. Adjust speed by electric control system

3. Through hydraulic and electric controled disk brakes to stop the machine

4. Using varies position indictor system to show the position of the container.

5. The whole equipment is controled , monitored and protected by a Machine, electricity, hydraulic combined system made of varies sensors and control components.

6. Through computer and net technology to realize information exchange between inside and outside of the mine hoist.

Mine Hoist Features:

1. large lift payload, long lift distance, high lift speed, small in size, more safty and reliability.

2. According to mine hoist technical requirement ,can be equiped with single brack disk or double brake disk friction wheel.Floor mounted friction mine hoist has a friction gasket with two rope races and rope direction adjusting device. Shaft tower mounted type is single rope race friction gasket.

3. The friction coefficient of gasket will not be less than 0.25 under the condition of without oil,water or using special grease.Fixed block and lock blockk are made of phenolic resin.

4. Head sheave and guiding wheel are arranged eccentriclly, and equiped with PVC gasket.

5. Rear mounted hydraulic cylinder disk brake has reasonable contructure, better sealing performance and low inner resistance.Disk brake controled by electric-hydraulic system.

6. Hydraulic station has two tyeps: low-middle pressure, middle-high pressure. Low-middle pressure station has electric time delay two levels brake system and hydraulic time delay two levels brake system. Middle-high pressure station has constant speed reduction two levels brake system and constant brake torque two levels system. Can be equiped with pressure switch, pressure sensor and pressure transmitter.

7. Equiped with speed detection transmission, backup protection, brake disk deflection detect device, wire rope slide detect device, Device for Turning of Ring Groove, etc..

8. Reducer adopts planetary gear reducer which has the features of light weight, high efficiency, long life span. Electric Control System can be AC PLC system or DC PLC system.

9. Four types console center equiped with integrated signal indicator for customer choosing. Two table types with new all-in-one operating handle,one of two table types with LCD computer display. Two split types equiped with digital deepth indicator, industrial TV or computer, print, specail table,etc..

10. Equiped with mine hosit NCS(Network Control System) and Remote Diagnosis System.

Sketch of Multi-Rope Friction Mine Hoist

Technical Parameters of JKMD(C) Series Multi-Rope Friction Mine Hoist

| Model | Friction Wheel Dia. | Head Sheave Dia. | Wire Rope | Max. lift Speed | |||||

| Max. Static Tension | Max. Static Tension Difference | Wire RopeDia. | Qty. | Interval | Rope out Angle | ||||

| t | t | t | t | mm | pcs | mm | degree | m/s | |

| JKMD-2.25x4(I)C | 2.25 | 2.25 | 10.5 | 5 | 22 | 4 | 300 | 50-80 | 10 |

| JKMD-2.8x2(II)C | 2.8 | 2.8 | 18 | 4.5 | 28 | 2 | 300 | 50-80 | 10 |

| JKMD-2.8x4(I)C | 2.8 | 2.8 | 33.5 | 9.5 | 28 | 4 | 300 | 50-80 | 10 |

| JKMD-3.5x4(I)C | 3.5 | 3.5 | 52.5 | 14 | 35 | 4 | 300 | 50-80 | 13 |

| JKMD-3.5x4(III)C | 3.5 | 3.5 | 52.5 | 14 | 35 | 4 | 300 | 50-80 | 13 |

| JKMD-4x4 | 4 | 4 | 68.65 | 21.58 | 39.5 | 4 | 350 | 50-80 | 14 |

| JKMD-4.5x4(III)C | 4.5 | 4.5 | 78 | 21 | 45 | 4 | 350 | 50-80 | 14 |

| JKMD-5x4(III)C | 5 | 5 | 91 | 22 | 49 | 4 | 350 | 50-80 | 14 |

| Model | Reducer | Roted Parts Equivalent Weight(Excluding Motor and Head Sheave) | Head Sheave Equivalent Weight | Outline Dimension (L*W*H) Excluding Motor | Weight (Excluding electric devices) | Max.Non-removable part | Head Sheave Weight | ||

| Model | Speed Ratio | t | t | m | t | Weight t | L*W*H | t | |

| m | |||||||||

| JKMD-2.25x4(I)C | XP560(2) | 11.5 | 4.83 | 1.2x2 | 7x9x2.1 | 30.5 | 8.6 | 2.105x2.720x2.720 | 2x0.6 |

| JKMD-2.8x2(II)C | 7.35 | 4.9 | 1.523x2 | 7.8x11x2.65 | 49.163 | 14 | 2.93x3.55x3.55 | 2x7.06 | |

| P2H630(2) | 10.5 | 5.16 | |||||||

| 11.5 | 5.23 | ||||||||

| JKMD-2.8x4(I)C | XP1000(2) | 7.35 | 9 | 3.44x2 | 10x10x2.65 | 67.858 | 17.9 | 3.12x3.55x3.55 | 2x11.6 |

| 10.5 | |||||||||

| 11.5 | |||||||||

| JKMD-3.5x4(I)C | XP1120(2) | 7.35 | 20.6 | 6.3x2 | 8.5x9.5x3 | 102.67 | 32.5 | 3.48x3.75x3.75 | 2x18 |

| 10.5 | |||||||||

| 11.5 | |||||||||

| JKMD-3.5x4(III)C | / | / | 18 | 6.3x2 | 7.5x9.5x3 | 82.55 | 35 | 4.710x3.75x3.75 | 2x18 |

| JKMD-4x4 | / | / | 17.23 | 6.5x2 | 9.5x9x3.2 | 90.936 | 15 | 2.13x4.31x4.31 | 2x20.4 |

| JKMD-4.5x4(III)C | / | / | 29 | 11.5x2 | 9.5x9.5x3.7 | 170 | 55 | 5.450x4.65x4.65 | 2x37.5 |

| JKMD-5x4(III)C | / | / | 38 | 13x2 | 9.5x10x4 | 182 | 23 | 2.15x2.76x5.52 | 2x41 |

- Pre:No

- Next:No

Tags: mine hoist, mine winder, mine winch, mine windlass